Newly released findings from McKinsey & Company and the World Economic Forum show that American manufacturing companies are lagging behind Fourth Industrial Revolution (4IR) innovations and could lose out on up to $3.7 trillion in value by 2025.

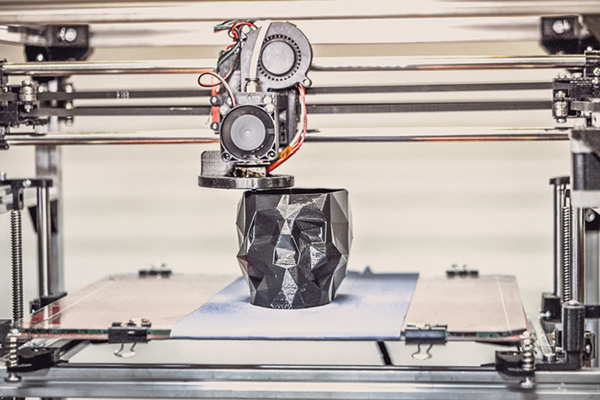

The report, Global Lighthouse Network: Insights from the Forefront of the Fourth Industrial Revolution provides key insights on how advanced manufacturing “Lighthouses” in the U.S. and around the globe succeed in the 4IR, harnessing automation, analytics, IoT and digitization, to connect their value chains end-to-end.

Top Findings Include:

- 70% of manufacturers are unable to bring manufacturing innovation to scale and are at higher risk of permanently falling behind lighthouses

- Europe and Asia are embracing 4IR much faster than the U.S., with 41 of 44 total lighthouses

- Companies are generating value from 4IR technologies beyond the factory: 14 of the 28 newly identified lighthouses are integrating end-to-end manufacturing innovation from their suppliers to their customers and beyond

- Job automation is forcing companies to evolve their operational models and upskill workers to use cognitive and creative skills that have no AI equivalent

The select few manufacturing sites found in the U.S. can be a beacon for a sector in need of innovation. For example, Johnson & Johnson Vision Care in Jacksonville, Florida, uses 4IR technology like virtual reality and digital twins improve the patient experience. J&J Vision Care has also digitally connected its value chain end-to-end from suppliers to consumers, and implemented reconfigurable manufacturing, helping them realize double-digit cost reduction and sales growth.

Source: World Economic Forum

Dr. Enno de Boer, Partner and Global Head Manufacturing at McKinsey, told SCMR in an interview that risk is still part of the equation.

“But the biggest risk we see is not moving fast enough,” he says. “For those who are moving quickly and at scale, we see real value being created. The secret is to combine technologies of the fourth industrial revolution, connect your value chain end-to-end, and do so at-scale.

Standing up several pilots that have a narrow scope simply do not return enough value, he adds, but instead place organizations in a netherworld of inaction.

“When the focus is on building something that is scaleable, it often results in greater connectivity, and becomes a differentiator for how supply chain mangers think about their role, work and opportunities.”

Furthermore, he says, global supply chain managers who don't embrace 4IR and rely on a smart follower strategy will undoubtably be left to languish in “pilot purgatory,” unable to bring manufacturing innovation to scale.

“The single most important lesson from our Lighthouse research with the World Economic Forum is that organizations need to move with greater urgency to scale because suppliers are less inclined to adopt a new technology if the space is already claimed. Delaying this transformation is no longer viable—companies that wish to remain competitive must embrace and scale their 4IR efforts.”

SC

MR

Latest Supply Chain News

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- There is still work to do to achieve supply chain stability

- Blooming success: The vital role of S&OE in nurturing global supply chains

- More News

Latest Resources

Explore

Explore

Business Management News

- AI, virtual reality is bringing experiential learning into the modern age

- Tips for CIOs to overcome technology talent acquisition troubles

- There is still work to do to achieve supply chain stability

- Blooming success: The vital role of S&OE in nurturing global supply chains

- Supply chain salaries, job satisfaction on the rise

- How one small part held up shipments of thousands of autos

- More Business Management

Latest Business Management Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks