COVID-19 has impacted the entire food and beverage (F&B) supply chain, from farm field to consumer. It has upended the sector’s operational capacity in its entirety, including production, processing, packaging, and distribution.

Though this is not the first global health pandemic to occur, it is taking place in a contemporary context marked by unprecedented increases in population size. As such, demand for large volumes of products has put enormous amounts of pressure on the F&B industry.

Consumer and purchasing behaviors have been heavily influenced by the COVID-19 pandemic. Shifting trends in this space have led to unanticipated and unparalleled shocks in the industry.

New operating procedures, often succeeding infection outbreaks, have led to plant closures and labor reductions. Limited production and output have been compounded by curtailed consumer spending, brought on by an impending global recession, increasing unemployment rates, and a general uncertainty of the sourcing landscape. At the same time, the shuttered restaurant industry has led to decreased demand for wholesale products.

This, augmented by labor capacity shortages, has led to food losses, inefficiencies, and waste. Though food shortages have been largely avoided on a global scale throughout the crisis, systemic weaknesses in F&B supply chains have disclosed vulnerabilities for many companies operating in this sector.

“The pandemic has caused a shift toward a greater need for efficiency in production amidst the long-term realities of staff capacity shortages and an unpredictable regulatory environment,” said Jena Santoro, Supply Chain Risk Intelligence, Resilience360. “The uncertainties of virus transmission have led many countries to adopt food protectionist policies, which has disrupted end-to-end supply chain continuity. It has increased the global price of food and beverage products and has made the global food supply more inaccessible.”

“In the short term, organizations operating in the industry must continue to adhere to local health measures, even at the cost of maximum efficiency, and work with risk monitoring tools to understand the impact of the outbreak on their supply chains,” she continued. “The pandemic has exposed the vulnerabilities of an industry historically reliant on manual labor. In the long-term, companies can introduce more automation and robotics technology in their supply chain to address labor shortages to mitigate the impact of future crises.”

The uncertainties of virus transmission have led many countries to adopt food protectionist policies, which has disrupted end-to-end supply chain continuity. It has increased the global price of food and beverage products and has made the global food supply more inaccessible. Reductions in passenger air travel have impacted air freight considerably, the method by which most perishable products are transported. Air freight capacity has declined over 80 percent on routes between Europe and Latin America.

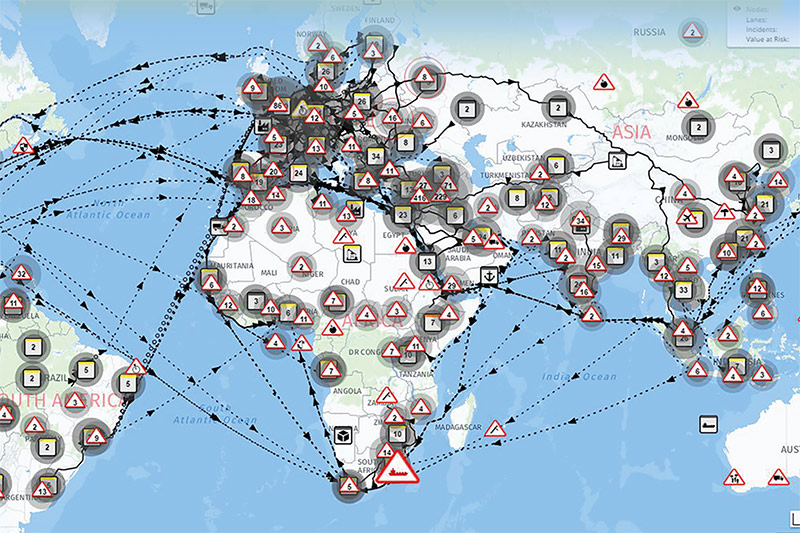

This Resilience360 Special Report, “COVID-19 Exposes Vulnerabilities in the Global Supply Chain” highlights the impacts that have been experienced by the F&B industry during the COVID-19 pandemic thus far.

It underlines the vulnerabilities of the industry that have been exposed as the result of the pandemic. This includes an overreliance on in-person, manual labor from farm harvest to food processing facilities. The report also calls attention to an inadequate focus on climate-controlled storage, transport, and preservative technologies. This, compounded by an increasing consumer demand for year-round access to fresh products, has led to a high dependency on expensive air freight, the cargo transport means most impacted by the virus. Like other industries, a tendency for companies operating in F&B to engage in single sourcing has disrupted business continuity during outbreaks. The COVID-19 pandemic has exposed the need for greater efficiency and adaptability vis-à-vis automation and diversified sourcing in the F&B industry.

“Companies should continue to adapt to shifting consumer behaviors and packaging demands,” said Santoro. “Acknowledge the consumer shift in demand toward individually packaged products and adjust packaging processes as such—this can include identifying additional suppliers of packaging solutions and adapting factory floor processes to cater to this evolving demand.”

“As well, we recommend that companies consider diversified sourcing as a long-term business strategy. Though the COVID-19 pandemic has been global in scale, intensified regional impacts have been felt at varying times.

For example, while E.U. transmission rates had largely plateaued around mid-summer, Latin America cases were trending upward. Dispersing operations in different parts of the world allows companies to quickly react to notifications of new outbreaks, shifting resources and operations to less-impacted parts of the world.”

As reported in SCMR last April, CBRE Research explored the relationship between e-commerce grocery growth and cold storage warehouse capacity in its Food on Demand Series, and found that the food industry is undergoing significant disruption from COVID-19.

“As U.S. consumers increasingly have groceries delivered directly to their homes or are buying online and picking up in store,” noted researchers.

SC

MR

Latest Supply Chain News

Latest Podcast

Explore

Explore

Business Management News

- Strengthening customer fulfillment: Building a strategic stakeholder network

- The hard job of teaching soft skills

- Trump picks former Wisconsin congressman Sean Duffy for DOT secretary

- Made in Mexico, manufactured by China

- Retail sales see gains in October, reports Commerce and NRF

- Balancing green and speed: Home delivery insights from the pandemic era

- More Business Management

Latest Business Management Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks