Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

November 2017

There are strands of sustainability and corporate responsibility through much of this month’s issue. James T. Prokopanko, the former CEO and president of The Mosaic Company, details how corporate responsibility became his compass for leader ship when he took over the reins of the company back in 2007. Similarly, Joseph Ludorf, the executive director of supply chain for Cipla Medpro, details how revamping the planning process enables the South African pharmaceutical company to prof- itably supply drugs to underserved populations on the continent as part of its corporate mission. We round out the issue with five tips for intelli- gent risk taking in… Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

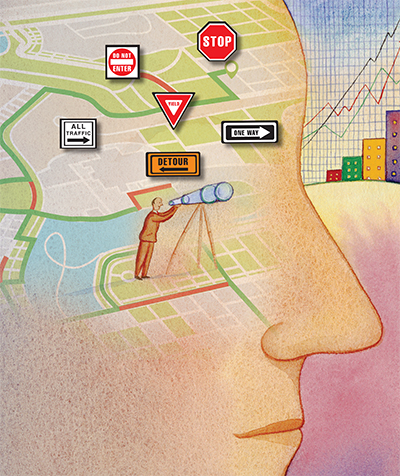

More often than not, tasks that should be simple in theory are, in fact, challenging. A routine commute from home to work can quickly become difficult and circuitous if unexpected lane closures and detours are presented. Inclement weather and uprooted trees in the road may cause more reroutes on the drive home.

While a supply chain manager’s goal is quite simple in theory (get the right products to the right location, at the right time, for the best price possible), often times achieving this goal can, in fact, be difficult. Despite the best laid plans, changing variables can affect supply chain efficiencies and present challenges to supply chain managers just as construction, traffic and detours can disrupt a commuter’s usual driving route and force him to find an alternative path in real time so as to minimize the risk of arriving late to work, missing a meeting or finding himself stuck in gridlock traffic.

Unfortunately, many organizations are not as well prepared to respond in real time when confronted with changes to their supply chain networks—and change is the only constant in life and supply chain networks. They struggle to adjust their networks to mitigate the effects of changing variables. While the commuter in the above example can simply select another route to work or home, stopping, starting and rerouting entire supply chain networks is not as easy or without cost, especially when the changes to be made are significant, such as identifying a new supplier in the middle of a promotion. Organizations also may lack the discipline or technology to routinely monitor for minor incidents and changes along the network that could signal an impending major event.

This is not to suggest that many organizations are not already implementing strategies and setting up processes to ensure their supply chain networks are optimized to achieve their defined business objectives. On the contrary, many are. They are taking the time to design networks where suppliers, manufacturing facilities, warehouses and distribution centers are optimally arranged. The process is often complex, requires organizations to make many assumptions and changes are most likely capital intensive. Because of this, organizations typically undertake these network design studies and optimization exercises only once every three to five years.

This complete article is available to subscribers only.

Log in now for full access or start your PLUS+ subscription for instant access.

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

November 2017

There are strands of sustainability and corporate responsibility through much of this month’s issue. James T. Prokopanko, the former CEO and president of The Mosaic Company, details how corporate responsibility… Browse this issue archive. Download a PDF file of the November 2017 issue.More often than not, tasks that should be simple in theory are, in fact, challenging. A routine commute from home to work can quickly become difficult and circuitous if unexpected lane closures and detours are presented. Inclement weather and uprooted trees in the road may cause more reroutes on the drive home.

While a supply chain manager's goal is quite simple in theory (get the right products to the right location, at the right time, for the best price possible), often times achieving this goal can, in fact, be difficult. Despite the best laid plans, changing variables can affect supply chain efficiencies and present challenges to supply chain managers just as construction, traffic and detours can disrupt a commuter's usual driving route and force him to find an alternative path in real time so as to minimize the risk of arriving late to work, missing a meeting or finding himself stuck in gridlock traffic.

Unfortunately, many organizations are not as well prepared to respond in real time when confronted with changes to their supply chain networks—and change is the only constant in life and supply chain networks. They struggle to adjust their networks to mitigate the effects of changing variables. While the commuter in the above example can simply select another route to work or home, stopping, starting and rerouting entire supply chain networks is not as easy or without cost, especially when the changes to be made are significant, such as identifying a new supplier in the middle of a promotion. Organizations also may lack the discipline or technology to routinely monitor for minor incidents and changes along the network that could signal an impending major event.

This is not to suggest that many organizations are not already implementing strategies and setting up processes to ensure their supply chain networks are optimized to achieve their defined business objectives. On the contrary, many are. They are taking the time to design networks where suppliers, manufacturing facilities, warehouses and distribution centers are optimally arranged. The process is often complex, requires organizations to make many assumptions and changes are most likely capital intensive. Because of this, organizations typically undertake these network design studies and optimization exercises only once every three to five years.

SC

MR

Latest Supply Chain News

Latest Podcast

Explore

Explore

Software & Technology News

- Nine questions are the key to AI success in building resilient supply chains

- Looking back at NextGen 2024

- AI is moving omnichannel closer to the customer

- How technological innovation is paving the way for a carbon-free future in logistics and supply chains

- Körber Supply Chain Software’s Craig Moore says MercuryGate acquisition is about the customer

- Robotic use grows by 10%

- More Software & Technology

Latest Software & Technology Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks