Managing through uncertainty is nothing new for supply chain leaders and is expected to be an ongoing challenge with further economic instability and geopolitical challenges projected. Today’s supply chain leaders are in a unique position to leverage their experience navigating uncertainty to devise a roadmap that shows how technology can help their businesses remain successful and drive competitive advantage, despite these uncertainties and pressures.

One such technology area that continues to draw interest for advancing supply chains is robotics. According to a Gartner survey of over 500 supply chain professionals, 51% of respondents said they believe robots are highly disruptive technologies, and about 60% also said that they believe these are highly important to their businesses.

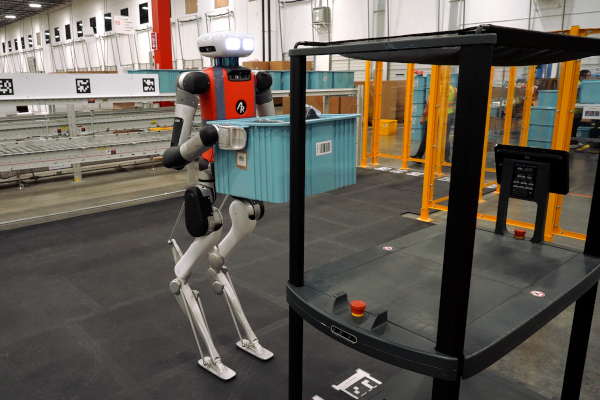

While supply chain demand for robots remains very high, in particular, Gartner predicts that by 2027, 10% of new intralogistics smart robots sold will be next-generation humanoid working robots. These AI-enabled robots—which resemble a human in shape and can interact in a natural human way—have the potential to be the missing link in fully automated warehouse processes.

Let’s take a closer look at robotics available today, as well as progress being made on humanoid robots.

Warehouse robotics today have limitations

Today, robots are principally useful for addressing repeatable tasks with minimal variance from activity to activity or for moving things around from one location to another. While useful to an extent, the immobile, inflexible and programmed single-activity architecture of traditional industrial robots has limitations. Today’s warehouses are dynamic environments with varied tasks that require a mobile and adaptable workforce.

We are already starting to see advancements being made to address the limitations of warehouse robotics. This includes successful examples of humanoid robots that adopt a human form factor using arms and legs to navigate, pick up, manipulate and move items.

Moving around and picking up individual items of varying sizes, shapes and orientations is difficult for robots, but easy for humans. As a result, we project humanoid robots will evolve during the next several years to address the limitations of previous generations of automation, and will provide the necessary cost savings, flexibility, adaptability and scalability that will generate large-scale investments from a range of different organizations.

Additionally, according to the same survey discussed earlier, around half of respondents cited rising labor costs and a similar number raised concerns about labor availability as notable reasons for investing in robotics. Humanoid robots can help with this challenge. They will differ from previous generations of smart robots by leveraging artificial intelligence and having the ability to collaborate that will help address some labor shortage challenges in supply chain-intensive industries.

Technology advancements driving progress

We are already starting to see advancements being made to address the limitations of warehouse robotics. This includes successful examples of humanoid robots that adopt a human form factor using arms and legs to navigate, pick up, manipulate and move items.

What makes next-generation humanoid working robots different is their ability to eventually obtain the level of adaptability that humans have, which will allow robots to be used and dynamically repurposed for many different activities without programming. Next-generation humanoid robots will compete with the current cost of labor for similar functions and will provide higher availability and reliability than the human workforce.

These robots can flexibly support the needs of the business by dynamically moving from process to process and taking on new activities without special programming. For example, the robot might perform receiving and putaway tasks in the morning and picking tasks in the afternoon just like humans do today. These developments are very exciting to supply chain and other industry leaders who have struggled with chronic labor challenges.

The path toward humanoid robots

The potential for humanoid robots is clearly alluring, but it would be a mistake for supply chain operations with high-volume, predictable and consistent processes to delay investments in more widely available and mature smart robots today. The pace of growth for humanoid robots will be complex and gradual, and organizations should begin by leveraging currently available robotics to enhance or supplement their human workforce.

Additionally, before pursuing humanoid robots, companies must start mapping their functional processes to determine which, if any, of these processes can be addressed with current generations of robots and which will benefit most from “human-centered” design. To do this, leaders should identify those processes that need high degrees of flexibility and adaptability and focus on learning how your human workforce performs these tasks to understand what capabilities a humanoid robot will need to support.

Because next-generation humanoid working robots are a nascent technology, companies must develop a structured methodology for conducting effective proofs of concept. Leading-edge companies are building robotics competency and collaboration centers (RCCC) to take on these roles.

About the author

Dwight Klappich is a research vice president and Gartner Fellow in Gartner's Supply Chain Practice. Dwight's research focuses on the strategic role logistics plays in leading-edge SCM organizations and how SCM leaders' technology strategies and tactics are differentiated from their peers. Dwight also leads Gartner's Intralogistics Smart Robotics research. His primary focus is on the role that technology plays in transforming logistics operations.

SC

MR

More Automation

- Körber Supply Chain Software’s Craig Moore says MercuryGate acquisition is about the customer

- Robotic use grows by 10%

- Understanding organized labor’s impact on our supply chain

- The art of winning at supply chain technology: Lessons from managing tech for the largest private trucking fleet in the U.S.

- How to identify and eliminate internal demons in supply chain management

- More Automation

What's Related in Automation

Explore

Explore

Topics

Software & Technology News

- Nine questions are the key to AI success in building resilient supply chains

- Looking back at NextGen 2024

- AI is moving omnichannel closer to the customer

- How technological innovation is paving the way for a carbon-free future in logistics and supply chains

- Körber Supply Chain Software’s Craig Moore says MercuryGate acquisition is about the customer

- Robotic use grows by 10%

- More Software & Technology

Latest Software & Technology Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks