Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

March-April 2020

Are you ready for NextGen technologies? Just the other day, I had the opportunity to tour one of Amazon’s highly automated robotic fulfillment centers. I expected to be dazzled—and I was. But it wasn’t because of the automation. The tour was a reminder that there’s no question that NextGen technologies such as Artificial Intelligence, blockchain, robotics, 3D printing and 5G are going to be the differentiators in tomorrow’s supply chain. The question is: Are you ready? Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

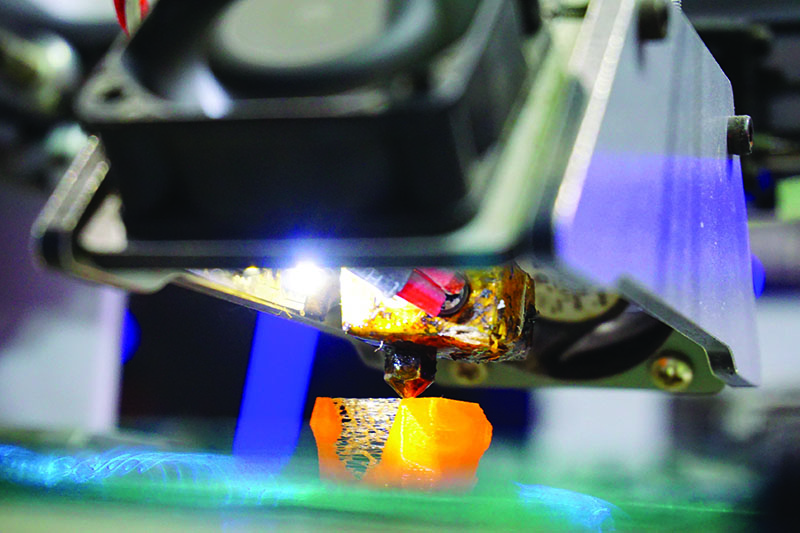

Disruption is the rule in supply chain management and manufacturing today. Although conventional supply chains remain the backbone of global commerce, most observers expect convention to make way for fundamentally new processes such as manufacturing on demand that involve additive manufacturing (AM) and 3D printing. That’s certainly our conclusion based on our research for this article, which included field studies of the customers of Fast Radius, a Chicago-based AM solutions company. Utilizing in-depth interviews with key personnel and a review of secondary sources, we’ve put together a best practices framework along with insights for supply chain managers who are considering AM in the context of their digital supply chains (see sidebar: About our research).

The story of additive manufacturing is similar to other disruptive innovations that made the leap from the fringe to the mainstream, such as the Internet, electric cars and social sharing platforms like Uber and Airbnb. While AM has a nearly 40 year history, it’s now poised to make that transition over the next decade. Capabilities and case studies continue to grow as the drawbacks to AM such as time, cost and material availability, continue to shrink. Forward-thinking companies such as GE, Seimens and Wassara are already reaping the benefits of AM (see sidebar: Putting 3D to work).

Early adopters aside, Industry 4.0 is forcing managers to think differently about where and how goods are manufactured and moved around the world. As a result, their digital offspring, aided by additive manufacturing (AM) and 3D printing, are gaining significant traction in the world of manufacturing and just-in-time fulfillment. Over the last decade, investment in AM research, technology and materials has skyrocketed. According to the 2019 Wohlers Report, the global AM market is expected to hit $15.8 billion in 2020, growing to $35.6 billion in 2024. This is dramatic growth from AM’s humble beginnings in the 1980s.

This complete article is available to subscribers only.

Log in now for full access or start your PLUS+ subscription for instant access.

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

March-April 2020

Are you ready for NextGen technologies? Just the other day, I had the opportunity to tour one of Amazon’s highly automated robotic fulfillment centers. I expected to be dazzled—and I was. But it wasn’t because… Browse this issue archive. Access your online digital edition. Download a PDF file of the March-April 2020 issue.Disruption is the rule in supply chain management and manufacturing today. Although conventional supply chains remain the backbone of global commerce, most observers expect convention to make way for fundamentally new processes such as manufacturing on demand that involve additive manufacturing (AM) and 3D printing. That's certainly our conclusion based on our research for this article, which included field studies of the customers of Fast Radius, a Chicago-based AM solutions company. Utilizing in-depth interviews with key personnel and a review of secondary sources, we've put together a best practices framework along with insights for supply chain managers who are considering AM in the context of their digital supply chains (see sidebar: About our research).

The story of additive manufacturing is similar to other disruptive innovations that made the leap from the fringe to the mainstream, such as the Internet, electric cars and social sharing platforms like Uber and Airbnb. While AM has a nearly 40 year history, it's now poised to make that transition over the next decade. Capabilities and case studies continue to grow as the drawbacks to AM such as time, cost and material availability, continue to shrink. Forward-thinking companies such as GE, Seimens and Wassara are already reaping the benefits of AM (see sidebar: Putting 3D to work).

Early adopters aside, Industry 4.0 is forcing managers to think differently about where and how goods are manufactured and moved around the world. As a result, their digital offspring, aided by additive manufacturing (AM) and 3D printing, are gaining significant traction in the world of manufacturing and just-in-time fulfillment. Over the last decade, investment in AM research, technology and materials has skyrocketed. According to the 2019 Wohlers Report, the global AM market is expected to hit $15.8 billion in 2020, growing to $35.6 billion in 2024. This is dramatic growth from AM's humble beginnings in the 1980s.

SC

MR

Latest Supply Chain News

- Unlocking retention: The role employee engagement plays

- Can supply chain managers embrace an entrepreneurial mindset?

- Challenges to ESG reporting

- With capacity to spare, logistics real estate demand remains subdued

- Tariffs, taxes and trade: The impact of Trump’s reelection on the supply chain

- More News

Latest Resources

Explore

Explore

Software & Technology News

- Nine questions are the key to AI success in building resilient supply chains

- Looking back at NextGen 2024

- AI is moving omnichannel closer to the customer

- How technological innovation is paving the way for a carbon-free future in logistics and supply chains

- Körber Supply Chain Software’s Craig Moore says MercuryGate acquisition is about the customer

- Robotic use grows by 10%

- More Software & Technology

Latest Software & Technology Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks