As we noted in “Leveraging “The Loop” Key to Profits This Year,” the volume of returned inventory continues to rise for supply chain managers in a variety of industry sectors.

“Towards the Circular Economy,” a recent report published by the Ellen MacArthur Foundation, notes that conversations about circular economy (CE) are increasing.

The concept – an economic model that encourages continuous reuse of materials to minimize waste, as well as driving demand for natural resource consumption – has been described by Gartner as starting “good design, end of life and raw material reuse in mind.”

According to Gartner analyst, Patrick Van Hull, 51% of logistics managers expect their focus on circular economy strategies to increase in 2021.

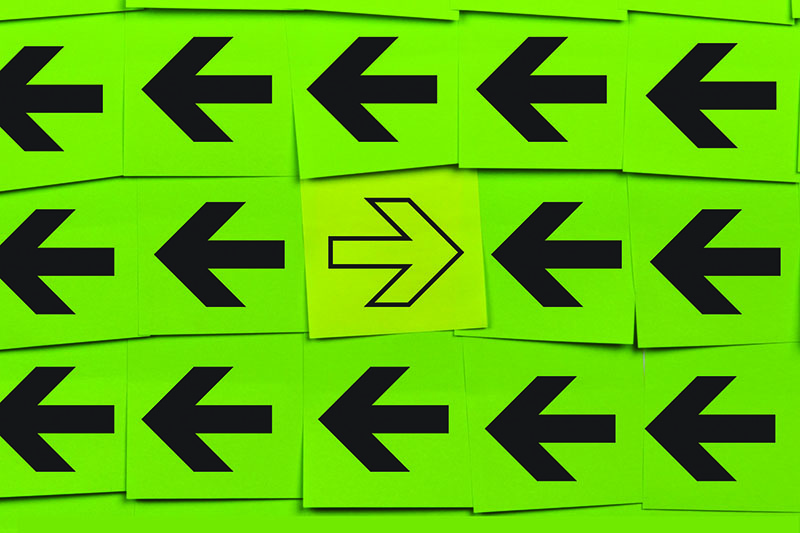

“This requires a complete shift in how we view supply chains, from a linear to a circular model, as companies will need to be able to access and reprocess end-of-life products,” he says.

Caterpillar, IKEA, Philips Lighting, Rolls Royce, Timberland and Nestle are all developing circular economy initiatives, while others are building “CE” departments and hiring talent, Gartner adds.

Consistent with the mission of reverse logistics, a circular economy is an industrial system that is restorative or regenerative by intention and design.

It replaces the end-of-life concept with restoration, shifts towards the use of renewable energy, eliminates the use of toxic chemicals, which impair reuse and return to the biosphere, and aims for the elimination of waste through the superior design of materials, products, systems and business models.

Such an economy is based on a few simple principles.

First, at its core, a circular economy aims to “design out” waste. Waste does not exist: products are designed and optimized for a cycle of disassembly and reuse. These tight component and product cycles define the circular economy and set it apart from disposal and even recycling, where large amounts of embedded energy and labor are lost.

Second, circularity introduces a strict differentiation between consumable and durable components of a product. Unlike today, consumables in the circular economy are largely made of biological ingredients or “nutrients” that are at least non-toxic and possibly even beneficial, and can safely be returned to the biosphere, either directly or in a cascade of consecutive uses. Durables such as engines or computers, on the other hand, are made of technical nutrients unsuitable for the biosphere, such as metals and most plastics. These are designed from the start for reuse, and products subject to rapid technological advance are designed for upgrade.

Third, the energy required to fuel this cycle should be renewable by nature, again to decrease resource dependence and increase systems resilience.

SC

MR

Latest Supply Chain News

Latest Podcast

Explore

Explore

Business Management News

- Strengthening customer fulfillment: Building a strategic stakeholder network

- The hard job of teaching soft skills

- Trump picks former Wisconsin congressman Sean Duffy for DOT secretary

- Made in Mexico, manufactured by China

- Retail sales see gains in October, reports Commerce and NRF

- Balancing green and speed: Home delivery insights from the pandemic era

- More Business Management

Latest Business Management Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks