Eeitor’s Note: Editor's note: Mark Dohnalek is President & CEO of Pivot International, the Kansas-based global product development, engineering & manufacturing firm.

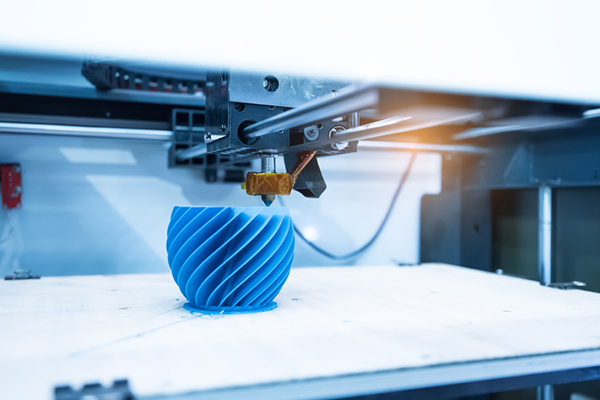

We know one thing for sure. In today's manufacturing, this is not your father's prototyping. And with the increased widespread adoption of 3D printing technology and its new accessibility and affordability, tomorrow's prototyping will continue to be dramatically different. Every day more forward innovations become available enabling legacy enterprises and agile startups with the ability to create, test, perfect and market their products. As a result, we are discovering new ways to operate, compete and scale exponentially. As the new year approaches, the final in this decade, we can anticipate these trends:

Increasing market differentiation.

Established companies, 30 years or older, have now accepted 3D printing as central to their business models. This means legacy enterprises have sophisticated understandings of the economic minutia of use-cases, cost-benefit analyses, and break-even points of 3D technology. They are the “power users” who continue to dominate the industrial manufacturing market. But, the new agile start-ups are using 3D printing to augment their core value proposition by integrating it into their larger workflow and operations. This small but mighty segment is growing rapidly, leading to a proliferation of “homegrown,” novel applications of 3D printing and to the creation of niche markets.

Greater availability of low-risk and high-reward.

Money savings and ease in accessibility will open up opportunities for individuals and small businesses. Before the widespread availability of 3D printing, it could be prohibitively expensive (if not impossible) for entrepreneurs to prototype a product on their own. This meant great ideas never had the chance to be made and marketed. But today, affordable 3D printers have reversed this situation, allowing even the smallest businesses to experiment with and market-test new designs. And because an incredibly broad array of 3D printing materials is now available, including plastic, glass, wood, concrete, metal, carbon fiber and more, unprecedented levels of customization are now possible. Over the next decade, affordable & accessible technology will provide a level playing field for businesses of all kinds and sizes to create and compete.

Innovations in different types.

3D printing technology has contributed to the development of “live prototyping” as an emerging best practice for agile organizations. Live prototyping is an innovative approach that is bridging the gap between rapid prototyping and piloting. By definition, rapid prototyping is a low fidelity approach that is designed to answer the question of how a particular problem can be solved. It focuses on generating ideas and testing rudimentary assumptions in very “rough” ways. (Through sketches, wireframes, Play-Doh models and so on.) Piloting is a high-fidelity approach used for the purpose of knowing if makes economic sense to scale. Pilot prototypes often look and function nearly identical to the actual products they are designed to market-test. They are the most “polished” of prototypes and the most expensive to produce.

Live prototyping leverages many of the advantages of both low fidelity and high-fidelity prototyping approaches. Like rapid prototyping, live prototyping is “rough” enough to keep costs down and operations agile, but like piloting, it is polished enough to allow for contextualized market-testing. (“Contextualized” here refers to the way that live prototyping enables a business to better determine how consumers will actually behave toward a product in “real life” rather than relying on potentially misleading consumer surveys and focus groups to glean this information.)

These processes and trends are changing the ways businesses operate and compete in economies of scale. Because widespread adoption of 3D printing is still in its early stages, this disruptive technology still holds immense untapped potential we can expect to see in the next decade. What the future of 3D printing holds is the cause for much speculation, but if the last ten years are any indication, we can expect to see innovation that will defy our current imaginations.

SC

MR

Latest Supply Chain News

Latest Podcast

Explore

Explore

Business Management News

- The hard job of teaching soft skills

- Trump picks former Wisconsin congressman Sean Duffy for DOT secretary

- Made in Mexico, manufactured by China

- Retail sales see gains in October, reports Commerce and NRF

- Balancing green and speed: Home delivery insights from the pandemic era

- AdventHealth named top healthcare supply chain by Gartner

- More Business Management

Latest Business Management Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks